https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot-emc-iron-ore-concentrate-1.jpg

754

1123

modir

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot22-cy-new-color-vector.jpg

modir2023-10-18 09:29:522023-10-18 12:12:07Iron Ore Concentrate

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot-emc-iron-ore-concentrate-1.jpg

754

1123

modir

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot22-cy-new-color-vector.jpg

modir2023-10-18 09:29:522023-10-18 12:12:07Iron Ore ConcentrateSTEEL INDUSTRY AT A GLANCE

- Steel production is highly energy and emissions-intensive, accounting for around 8% of global energy demand and 7% (2.6 Gt CO2) of total emissions from the energy system. This is more than the amount generated by all road freight today. Its large contribution stems largely from the sector’s high reliance on coal, which supplies 74% of its energy inputs.

- Steel is an indispensable material in modern society. Buildings and infrastructure are a key source of demand, but steel is also a critical ingredient for several modes of transport (e.g. cars, trucks, ships and rail), household products (e.g. utensils, appliances and furniture) and many other items besides. It also plays a vital role in the global economy, with over USD 2.5 trillion in revenue and employing around 6 million people globally.

- Steel is a highly traded commodity and is often in the spotlight of trade negotiations. The People’s Republic of China accounts for more than half of global steel production today and – despite high domestic demand – it is also the largest exporter, followed by Korea, Japan and the Russian Federation. The steel industry is highly competitive and fragmented. The top 10 producers account for just 25% of global production, which is low compared with other sectors, such as aluminum.

- Steel-making has two main metallic inputs: iron ore and recycled steel scrap. Around 70% of the total metallic input to steel production globally is derived from iron ore, with scrap making up the rest. Primary steel production refers to operations where iron ore is the main input, but scrap typically accounts for up to 15-25% of the metallic input in primary production. The blast furnace is the major piece of equipment used for primary steel-making, with this route accounting for 90% of production from iron ore. Secondary (or scrap-based) production is carried out in electric furnaces and is around one-eighth as energy-intensive as production from iron ore, using electricity – as opposed to coal – as the main energy input.

- Energy and raw materials account for 60-80% of steel production costs combined. Energy efficiency improvements in recent decades have led to modest reductions in energy consumption and emissions, but each ton of steel produced today still results in 1.4 t CO2 of direct emissions on average.

- Global steel production capacity is relatively young, with blast furnaces only around 13 years old on average, counting the last major refurbishment, relative to a typical lifetime of 40 years. Strategies to deal with existing assets are integral to realizing a sustainable transition for the sector.

Ref: Iron and Steel Technology Roadmap, IEA

Our Steel Products

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot-emc-iron-ore-concentrate-1.jpg

754

1123

modir

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot22-cy-new-color-vector.jpg

modir2023-10-18 09:29:522023-10-18 12:12:07Iron Ore Concentrate

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot-emc-iron-ore-concentrate-1.jpg

754

1123

modir

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot22-cy-new-color-vector.jpg

modir2023-10-18 09:29:522023-10-18 12:12:07Iron Ore Concentrate https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/spirally-welded-pipe-tot-company-2.jpg

754

1123

modir

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot22-cy-new-color-vector.jpg

modir2023-10-18 09:26:392023-10-18 12:12:16Spirally Welded Pipe

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/spirally-welded-pipe-tot-company-2.jpg

754

1123

modir

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot22-cy-new-color-vector.jpg

modir2023-10-18 09:26:392023-10-18 12:12:16Spirally Welded Pipe https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot-emc-carbon-steel-seamless-pipe-1.jpg

754

1123

modir

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot22-cy-new-color-vector.jpg

modir2023-10-18 09:23:132023-10-18 12:22:05Seamless Pipe

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot-emc-carbon-steel-seamless-pipe-1.jpg

754

1123

modir

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot22-cy-new-color-vector.jpg

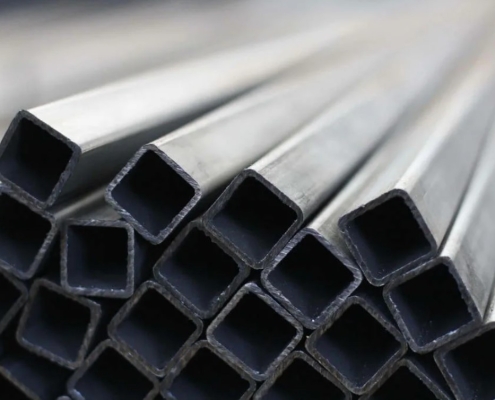

modir2023-10-18 09:23:132023-10-18 12:22:05Seamless Pipe https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot-emc-steel-profile.jpg

754

1123

modir

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot22-cy-new-color-vector.jpg

modir2023-10-18 09:12:472023-10-18 12:21:35Steel Profile

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot-emc-steel-profile.jpg

754

1123

modir

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot22-cy-new-color-vector.jpg

modir2023-10-18 09:12:472023-10-18 12:21:35Steel Profile https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/steel-rebar-1.jpg

754

1123

modir

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot22-cy-new-color-vector.jpg

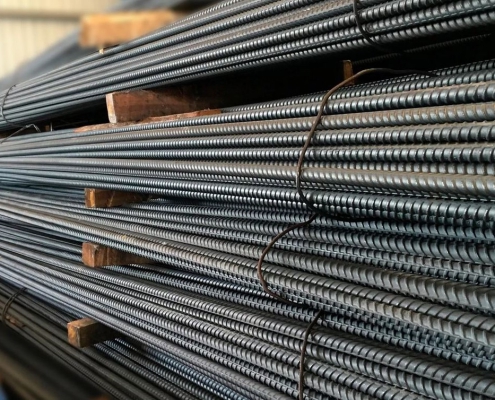

modir2023-10-18 09:09:462023-10-18 12:21:44Steel Rebar

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/steel-rebar-1.jpg

754

1123

modir

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot22-cy-new-color-vector.jpg

modir2023-10-18 09:09:462023-10-18 12:21:44Steel Rebar https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/billet.jpg

754

1131

modir

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot22-cy-new-color-vector.jpg

modir2023-10-18 08:48:542023-10-18 12:21:58Steel Billet

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/billet.jpg

754

1131

modir

https://cdn.ov2.com/content/tot_emccom_ov2_com/wp-content_85/uploads/2023/09/tot22-cy-new-color-vector.jpg

modir2023-10-18 08:48:542023-10-18 12:21:58Steel Billet