SPIRALLY WELDED LARGE DIAMETER PIPE

Spirally Welded Large Diameter Pipe is a type of steel pipe characterized by their unique manufacturing process, which involves forming a continuous spiral seam along the length of the pipe. The result is a strong, durable, and cost-effective solution widely used in various industries for fluid transportation, structural applications, and more.

These Spiral pipes are produced based on the modern two-stage method of welding known as offline which occupies a fundamental role in improving the quality and quantity of manufactured spiral pipes. In this method, the seam is first tacked by gas shielded metal are welding (GMAW) immediately after the pipe is shaped and then, the final welding process is performed by the double-joint stations at the same time as the seam submerged are welding (DSAW) process.

Strength and Durability, Flexibility and Versatility, Efficient Installation, Cost-Effectiveness are key features of TOT Company’s Spirally Welded Large Diameter Pipe.

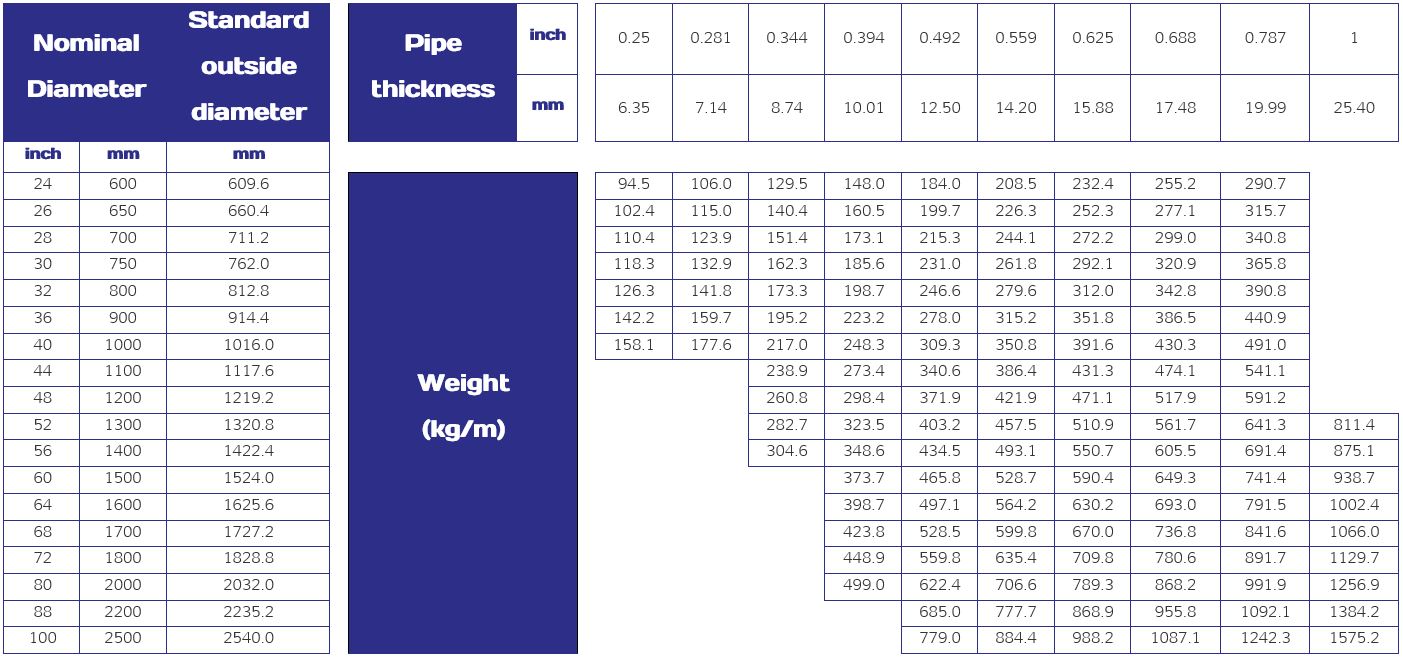

Standard outside Diameter: 609.6-2540 mm

Nominal Diameter:600-2500 mm

Pipe thickness:6.35-25.40 mm

Standard: NACE, AWWA, API

products matrix

SPECIFICATIONS

Depending on your requirements, TOT Company have specific solutions.

Whether it’s fluid transportation, structural applications, or HVAC systems, TOT Company supply Spirally Welded Large Diameter Pipe which provide an efficient and dependable choice for various industries. Stay connected with TOT Company as we bring you more exciting updates and improvements.